Measuring laser output in medical equipment manufacturing for FDA approval

Friday, March 22, 2024

Friday, March 22, 2024

Application: Medical laser welding, ablation and cutting

Measurement type: Laser power and energy measurement

The customer is a well-known player in the medical industry. They are dedicated to transforming lives through innovative medical solutions that improve the health of patients around the world.

As part of their prototyping and manufacturing activities, they use several lasers for welding, ablation, and cutting purposes. Many of them with different specifications since they are all optimized for different materials and thicknesses.

One laser model they have several of is the ILT Glovebox laser welding system made by IPG Photonics. The ILT Glovebox is designed for precision laser welding of hermetic medical devices.

To maintain FDA approval for the products they manufacture, they need to measure their laser output, and they need to do it the way it complies with FDA requirements. Otherwise, they will lose the right to sell this medical equipment in the USA for a year, which would have catastrophic consequences for their business.

The responsibility is on them to demonstrate that their lasers operate as intended. The stakes are high for their business. They must measure accurately.

Another challenge they face is that their FDA approval must be renewed each year and laser beam measurement instruments need to be recalibrated regularly to be compliant with FDA. Therefore, there is a product lifecycle management challenge here.

Regarding the lasers, they work with a wide range of specifications to perform laser welding on different metals. Wavelengths are anywhere from 520 nm to over 10 µm. All lasers are pulsed, some with slow repetition rates of 1-10 Hz, others in the kHz and MHz range, and everything in between.

The customer has measurement needs for both energy and power for quality control of their lasers. They measure either daily or weekly depending on how critical the laser system is.

Since they have so many different lasers, their manufacturing engineers and quality technicians prefer detectors that cover as many of them as possible. Therefore, when analyzing their needs, Gentec-EO’s measurement experts prioritize solutions that cover the largest measurement range possible.

To measure their ILT Glovebox, Gentec-EO’s team recommended two detectors since the system has two lasers that work for different processes. For the laser welding systems at 1064 nm, they opted for our QE50LP-S-MB-D0 energy detector.

QE50LP-S-MB-D0 laser energy detector

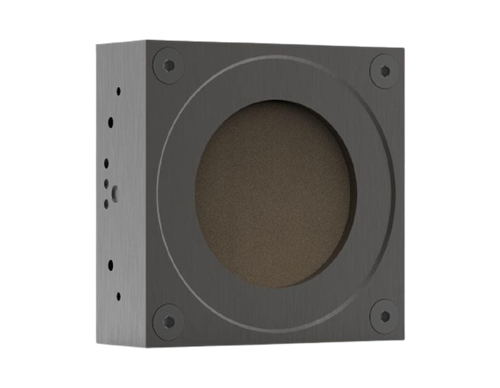

For the ablation process at 9.3 µm, we recommended our UP55N-40S-H9-D0.

UP55N-40S-H9-D0 laser power meter

Both detectors are connected to an S-LINK-2.

S-LINK-2 PC interface for power & energy measurement

All of these laser output measurement instruments are custom solutions based on standard products developed for them by Gentec-EO to meet their unique requirements and calibration needs. For example, the S-LINK-2 has been modified with an RS-232 connection rather than the USB or Ethernet standard one, the energy detector is tuned for longer pulses than our standard version and the power detector has a custom CO2 calibration to correct the measurement at 9.3 µm.

They have also bought several standard products from our QE12 and QE25 series of pyroelectric energy detectors and from our UP12 and UP19 series of thermopile power detectors for other wavelengths. These product series are versatile and among our best sellers.

Of course, all calibrations are NIST-traceable and Gentec-EO is ISO 17025 accredited, which is a must in the medical industry.

This medical customer has been relying on Gentec-EO’s measurement technology since 2002 to comply with FDA requirements.

They particularly enjoy our fast turnaround time for regular recalibration. This is important in the medical industry since they need to recalibrate to remain compliant and they are often on a tight schedule. Last year alone, they sent over 100 units to us to get recalibrated.

Many of their measurement instruments have been in use for more than 10 years. This level of reliability and continuous product support matters a lot in their business since any instrument change has an impact on their quality control process and requires the new instrument to be approved by the FDA.

They also have some units with three-point calibration. This is a big advantage for them since not many companies are open to custom products and calibration for small orders.

Gentec Electro-Optics specializes in laser beam measurement and analysis. With an outstanding 50-year track record of innovation, developing and providing state-of-the-art technologies to the laser market, Gentec-EO has become The Expert of the laser beam measurement field.

Gentec-EO offers the broadest range of off-the-shelf and custom laser beam measurement solutions. Challenge us with your laser specs and system requirements and we'll come up with the measurement solution that meets your needs.

Request a free consultation with a laser beam measurement expert