LLNL achieves nuclear fusion ignition: See where Gentec-EO laser energy meters are used

Thursday, January 26, 2023

Thursday, January 26, 2023

On December 13th 2022, the U.S. Department of Energy announced that Lawrence Livermore National Laboratory (LLNL) achieved nuclear fusion ignition at the National Ignition Facility (NIF) in Livermore CA, USA. NIF is a pulsed laser-based Inertial Confinement Fusion (ICF) research device which produced 3.15 MJ of energy on December 5th, using 2.05 MJ of laser energy provided in one shot lasting a few nanoseconds.

By proving that ICF can yield positive gain, this announcement values more than 50 years of research at the world’s most energetic laser facility, paving the way towards unprecedented capability to support the U.S. Stockpile Stewardship Program and more successful deuterium-tritium fusion reaction shots in the future. In hopes, one day, to generate cost-effective, non-radioactive, decarbonized electricity to the grid.

Read the official statement here. Watch LLNL’s video National Ignition Facility achieves fusion ignition.

The other main prospect for harnessing nuclear fusion to create electricity is by using large magnets to confine and accelerate hot plasma. Several hybrid designs are currently explored, as well as various fuel combinations (deuterium-tritium, deuterium-helium-3, hydrogen-boron-11, etc). Advancements in one technique can benefit the entire community. We live in exciting times for fusion.

LLNL is partnering up with Gentec-EO for the integration of custom laser energy detectors to measure the energy. In this article we present where the energy detectors are used in the NIF laser system, taking part of the impressive list of hardware utilized in this record-breaking achievement.

Gentec-EO is proud to answer the needs of the National Ignition Facility at Lawrence Livermore National Laboratory for laser beam diagnostics, energy measurements and calorimeters control solutions. We would like to thank them for the continued trust and valuable interactions.

Congratulations to all the people and teams working at NIF for the record yield of energy!

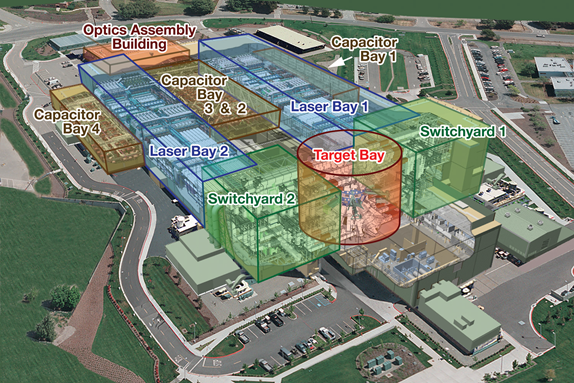

The Description of the NIF Laser article by Spaeth et al. is a great place to start. The NIF laser system is made of 2 Laser Bays containing each 2 clusters of 48 beams for a total of 192 laser beams. These 192 beams are amplified in the Laser Bays then directed through the Switchyards to the Target Bay where a 1 cm enclosure called hohlraum hosts a 2 mm-diameter pellet containing the two hydrogen isotopes we want to fuse together.

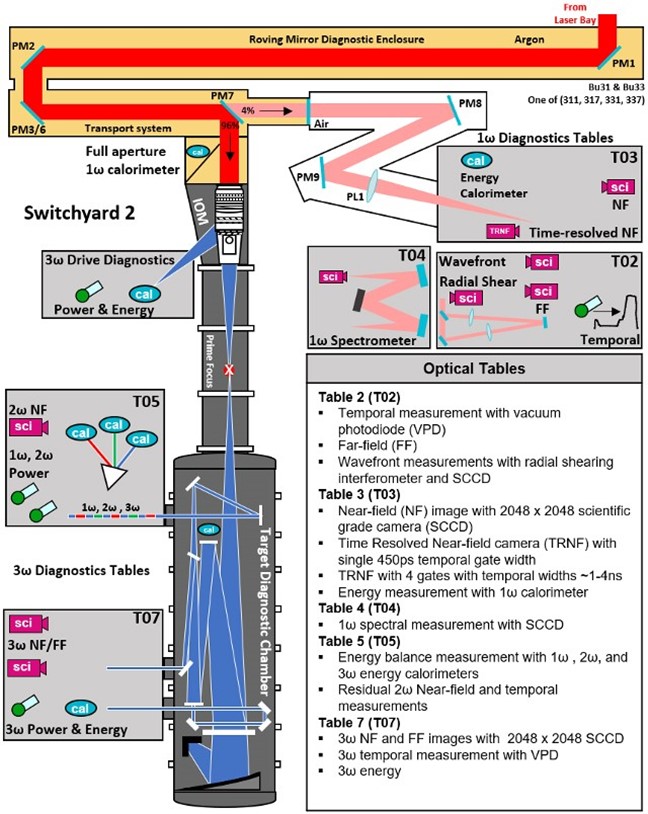

NIF has the size of 3 football fields to host 192 laser beams directed towards a 2-mm target (Fig 5. of Description of the NIF Laser article by Spaeth et al.)

The 4 clusters are supported by 4 Capacitor Bays to store the 300 MJ of electrical energy needed to power the large laser amplifiers operating to provide a 2.05 MJ laser shot. Breakeven in terms of total energy consumed versus total energy released is not there yet but this is not the primary goal of this facility. They achieved breakeven in terms of injected laser optical energy versus the total released energy, using a design initiated in the 1990’s and operations starting in 2009 for high-energy-density science experiments.

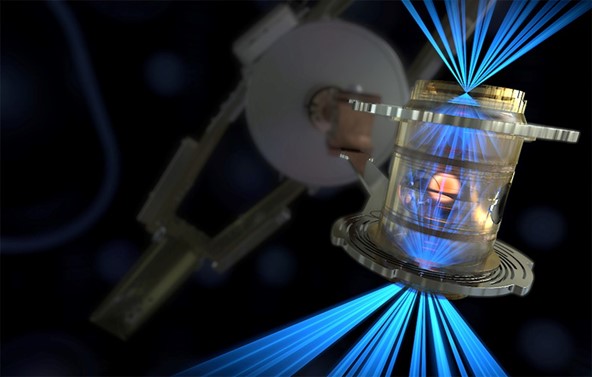

192 laser beams of 351 nm wavelength enter the hohlraum (image courtesy of Lawrence Livermore National Laboratory)

The 192 initial laser beams have a wavelength of 1053 nm. It becomes 351 nm after a process called frequency tripling. Then they enter both sides of the hohlraum and by hitting the inner walls of the hohlraum, the 351 nm energy is converted into X-rays, finally used to compress and heat up the spherical fuel capsule made of deuterium and tritium at the center. This is where nuclear fusion is triggered.

The goal to obtain more energy released by fusion than the total laser optical energy injected in the hohlraum was achieved on December 5th, 2022.

Let’s take a closer look at a few examples where laser beam measurements are made using custom-designed Gentec-EO calorimeters in this setup.

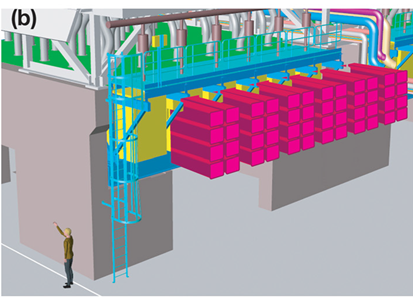

Each of the 4 clusters (with 48 laser beams in each, emitting at 1053 nm wavelength) is made of 6 bundles. Each bundle is made of 8 beams, vertically-aligned in 2 series of 4 square beams. This is how the NIF amplifiers are stacking up currently, in 1 cluster.

2 x 4 x 6 = 48 lasers emitting at 1053 nm in 1 cluster (Fig 49. (b) of Description of the NIF Laser article by Spaeth et al.)

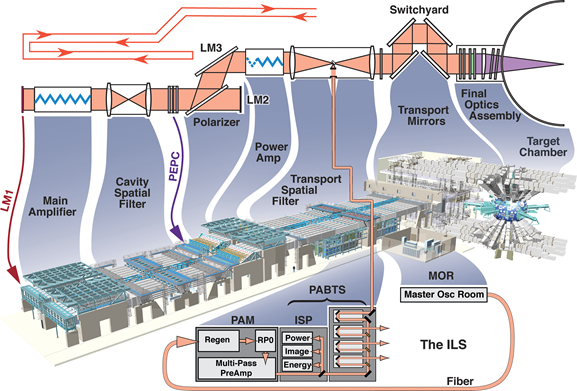

After a section called Transport Spatial Filter, the beams pass through a Diagnostic Beamsplitter. Then they enter the Transport Mirrors, a section also called Switchyard. Between the Switchyard and the Target Bay, frequency tripling is performed. The fundamental laser wavelength (1053 nm, called the 1 Omega or 1ω emission frequency) is converted to the required 351 nm laser wavelength (the 3 Omega or 3ω emission frequency) by the Final Optics Assembly, in vacuum, just before hitting target.

1 Laser Bay containing 2 clusters of 48 1ω Main Laser beams each (Fig 6. of Description of the NIF Laser article by Spaeth et al.)

The laser energy at fundamental wavelength (1053 nm) is measured after being transmitted through the Diagnostic Beamsplitter system using Gentec-EO custom, 420 mm square glass calorimeter detectors. They are referred to as the Roving Calorimeter (RCAL) which are full aperture 1ω calorimeters. There is one additional RCAL in the Precision Diagnostic System (PDS) overview schematic in the article New Laser Testing System Brings NIF Back to the Future.

The Precision Diagnostic System that was recommissioned in 2021 at NIF

Placed on motorized stages in the Roving Mirror Diagnostic Enclosure (RMDE), 2 series of 4 vertically-aligned RCALs move towards the laser beam bundles when laser energy measurements are needed.

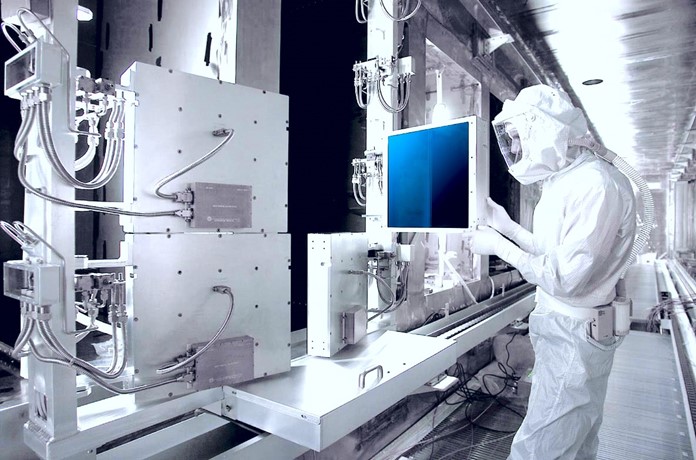

In this photo, we can see several Full aperture 1ω calorimeters mounted on the motorized stage that translates from one bundle to another. Only 6 detectors are visible but there are indeed 2 series of 4 vertically-aligned detectors stacked up in this cluster, used to move towards the 8 laser beams in each bundle.

Maintenance done on Full aperture 1ω calorimeters placed on a motorized stage at NIF (photo courtesy of LLNL)

Between high-energy-density science experiments and fusion shots, when the detectors are not verified or reconfigured as shown here, they can pivot 90 degrees to enter the laser beam paths and fully block the beams to take energy measurements. We show the back of 3 detectors in the picture used here.

Custom Gentec-EO calorimeters at NIF (photo courtesy of Lawrence Livermore National Laboratory)

For diagnostics purposes, we can measure the 96% of the full 1ω energy provided in the RMDE as shown in the PDS schematic. Let’s say we take the successful shot of December 5th with 2.05 MJ of energy injected in the hohlraum (resulting in the record-breaking 3.15 MJ of energy produced), that makes more than 10 kJ of optical 1ω energy per laser beam to safely block and measure in argon, with a maximum of 33 ns pulse width.

The current NIF laser repetition rate is minimum 8 hours between full system shots. The typical minimum repetition period for the Gentec-EO full aperture 1ω calorimeters integrated at NIF is 30 min and they are designed for use in air.

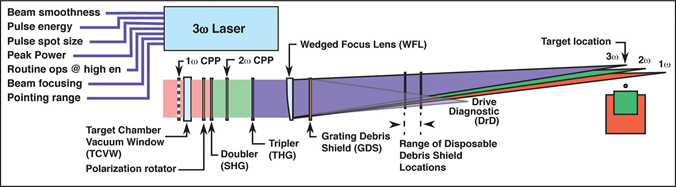

When comes the time to measure the 3ω laser energy that actually hits the hohlraum, that happens all in vacuum. Between the Switchyards and the Target Bay, there are the Final Optics Assemblies (FOA) made of Integrated Optics Modules (IOM) that performs the frequency tripling (going from 1053 nm to 351 nm).

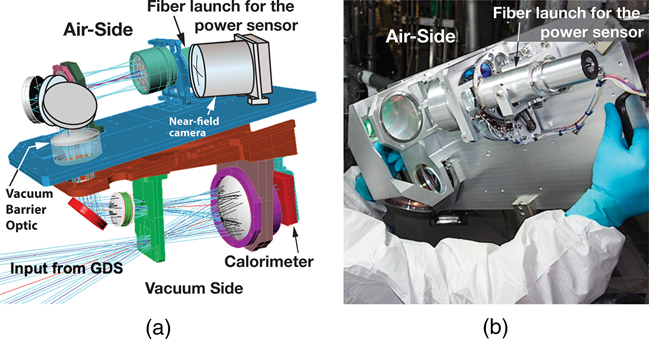

Various custom detectors from Gentec-EO are provided to NIF for use in vacuum, such as the large one pictured below, inside the Target Diagnostic Chamber (TDC), part of the PDS assembly which is designed to diagnose a single laser beam from 1 of 4 beamlines, coming from Laser Bay 2, before it enters the Target Bay.

Alignment of a calibration calorimeter inside the NIF Precision Diagnostic System TDC for use in vacuum (photo courtesy of LLNL)

Smaller Gentec-EO calorimeters are provided to integrate the Drive Diagnostics apertures (DrD) placed after that the frequency tripling is performed by the IOM.

The Integrated Optics Modules of the Final Optics Assemblies perform frequency tripling in vacuum (Fig 85. of Description of the NIF Laser article by Spaeth et al)

The multiple 110 mm square custom calorimeters are placed on the vacuum side of the DrD where they provide energy measurements for all the 192 NIF 3ω beams. The final optics are protected by a Grating Debris Shield (GDS), which serves as an optical pick-off in front of the detectors to decrease the amount of energy received.

The GDS in the final optics assembly protects optics and provides the optical pick-off for the 3ω energy detector, in red (Fig. 111. (a) of Description of the NIF Laser article by Spaeth et al.)

Single-shot energy calorimeters make one of the few product lines carried out by Gentec-EO where there is no off-the-shelf product available. These applications require unique, customized solutions for the measurement environment.

It is made on demand to safely block and measure the most powerful pulsed laser beams. For operation either in air or at a given vacuum level, with optical calibration or electrical calibration, when in need to quantify the detector’s response linearity with energy, repeatability, noise level... No calibration? Use of specific water fittings, brackets for mounting, use of standard monitors or custom control interfacing with automated acquisition for analyzing data?

For example, the typical damage threshold for the calorimeters used at NIF with a 5 kJ flat-top beam, 7 ns pulse width, single-shot, is 3 J/cm2 at 1053 nm, and serial commands have been standardized to communicate with the detectors.

We keep room for safety in our specifications and can currently measure above 15 kJ in the nanosecond regime but most importantly, we make them tailored to the exact requirements provided by our customers. We love a good challenge!

Given the rapid development of laser technology, we can’t wait to see what the next laser energy measurement requirements will be, and how wall-plug efficiency in the context of ICF will improve to achieve a total energy released superior to the total energy consumed.

Do you have a project that requires custom laser beam measurement solutions? Get in touch with us, we can help.