Let’s start this article by discussing the various types of detectors that can be used for this purpose and the differences between them. This will help you understand why a pyroelectric detector is a great choice and how it provides some advantages over other types of detectors.

Technologies used to measure laser power

The three most common detectors used for optical or laser power measurements are photodiodes, thermopiles, and pyroelectrics. This is not to say that there aren’t others, like water calorimeters, Golay cells, micro-bolometers to name a few, but they are on the periphery of mainstream optical power measurements.

Photodiodes

Photodiodes are of course very sensitive, capable of measuring from picowatts to hundreds of milliwatts (with ND filters). Each type, be it Silicon, Germanium, or InGaAs has a very distinct spectral range and spectral response (i.e. they are not spectrally flat). The upper limit of power they can handle is linked to something called “photocurrent saturation”. Once saturation is reached, the current output is no longer proportional to the laser (or light) intensity.

Thermopiles

Thermopiles are broadband, thermal detectors that are the mainstay for measurement of medium to high power lasers. The power range is typically from a few milliwatts to many kilowatts. They also provide a very high damage threshold on the order of tens of kW/cm2 and have large absorbing surfaces from 10 mm to 100 mm diameter. As these detectors respond to all sources of radiation (optical or heat) making measurements in the mW range can be a challenge due to DC thermal drift.

Buyer's checklist for laser power & energy meters

Ensure you purchase the most optimal solution for your measurement needs with this checklist.

Download it now, it's helpful and free!

Pyroelectric detectors

Pyroelectric detectors, which are AC coupled thermal devices, provide stable power measurements from a few nanowatts to several hundred milliwatts (typically 50 mW/cm2 maximum average power). Their spectral response is quite flat (± 2%) from 0.25 to 10.6 µm. They are typically used with an optical chopper running at between 5 and 25 Hz and mated to electronics that lock onto their AC voltage output. This provides the ability to ignore steady-state background radiation, unlike photodiodes and thermopiles. A pyroelectric detector only measures the chopped or modulated radiation it receives at a specific frequency.

How to accurately measure optical power with a pyroelectric detector

Choosing the appropriate pyroelectric detector for your application

From this paragraph on we’ll focus on the choices you need to make and things you need to do when measuring optical or laser sources with a pyroelectric radiometer (or power meter). By the way, we sometimes use the term radiometer for a calibrated instrument that is used to measure the output from electromagnetic sources (lamps, lasers, etc.) in radiometric units, like watts (radiant flux) and watts/cm2 (irradiance).

Here are some things to consider when deciding on the appropriate pyroelectric detector:

- Select a detector whose size will accommodate your laser beam diameter if you want to measure total radiant flux (i.e. watts). If you’re measuring irradiance (W/cm2) then your source will overfill the detector area. Make sure you know the precise area of the detector in that case.

- Also make sure you’ve chosen one that has sufficient sensitivity for your measurement.

- Look at either the “minimum measurable power” specified in watts.

- Or the “NEP” (noise equivalent power) specified in watt/(Hz)1/2.

- A typical rule of thumb about signal-to-noise is 20 to 1 (i.e. the power you hope to measure should be at least 20 times higher than the NEP).

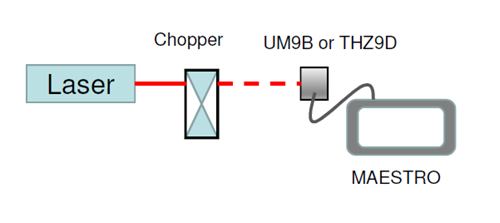

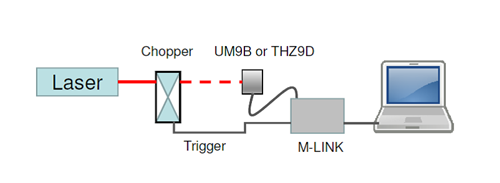

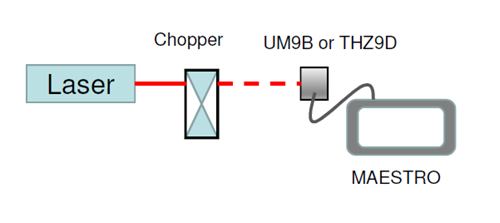

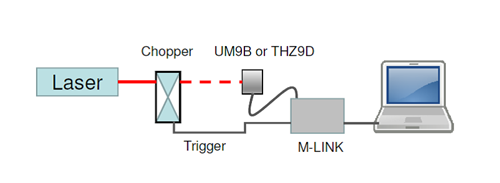

- You’ll likely want a pyroelectric power detector that plugs into a display or PC interface like our MAESTRO or M-LINK. Our UM-B and THZ-D series are detectors that mate to these two instruments.

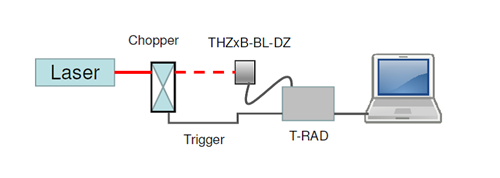

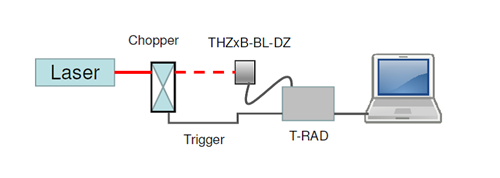

- Another choice is our broadband T-RAD single frequency, digital lock-in amplifier which is used with pyroelectric detectors of the THZ-B series. The detectors have apertures of 2.5, 5 and 9 mm diameter. This combination provides the highest performance of the products mentioned.

- In all cases, you’ll also need to use a stable optical chopper like our SDC-500 to modulate your CW or Quasi-CW source.

Please review the optical set-up drawings below.

Step-by-step procedure for making an accurate measurement

Next, we’ll describe the steps you’ll need to take to make an accurate measurement of your source’s optical power:

- Mount the pyroelectric power detector onto your optical table or rail using the “Delrin” post we provide. Do not use a metal post as this can couple mechanical noise into the detector (i.e. microphonic noise).

- Place the optical chopper close to your source and, if space permits, move the detector some distance away. This will effectively limit the field of view of the detector, essentially minimizing the background radiation.

- Make sure to set the chopper frequency to that required for a particular probe. It will either be 5 Hz, 10 Hz, or 25 Hz.

- If you’re using the LIA (“Lock-In Amplifier”) based instrument, you’ll want to connect the chopper sync output to the instrument trigger input.

- Also consider your measurement environment:

- Remove any sources of heat that the sensor might respond to.

- Be careful to shield the detector from air currents in your lab (like air conditioning outlets). You might want to use an extension or lens tube screwed into the front bezel of the probe for this purpose.

- Remove any sources of vibration like pumps or fans, if possible, as these are sources of mechanical/microphonic noise.

- Now, with the source blocked, power on the meter and allow it to come to thermal equilibrium. This can take 5 to 20 minutes depending on the starting temperature of the probe relative to the measurement environment. Note that your baseline power reading should become stable.

- Make sure to select the wavelength correction needed for your particular laser. This will ensure the best accuracy for your measurement.

- This is a good time to note the approximate noise floor of the power meter set to a particular range. When you unblock your source, you’ll want the power measurements to be about 20 to 30 times this noise floor, for accuracy.

- Next, remove the beam block and make sure the detector is centered on the source. It is also a good time to make sure you’re on the appropriate range. The measurement should be greater than 10% of the full range (i.e. > 2 mW on the 20 mW range).

- Now block the source again and use the “zero” or “offset” button or feature to cancel out the background.

- You’re now ready to make a measurement of your source’s optical power.

- Use the statistics mode whenever possible to enhance the accuracy of your measurement.

Summary

Pyroelectric detectors provide power measurement over a wide dynamic range, from 10 nW to 200 mW and from DUV to far-IR. They have relatively flat spectral response, which makes them especially good for broadband sources. They operate at room temperature which makes them very convenient to use. They also are inherently fast compared to other thermal detectors, which allows you to see fluctuations in the power of your source at rates under 100 milliseconds.

If you have questions about this article or your optical power measurement, don’t hesitate to contact our sales representatives.

Gentec-EO

Gentec Electro-Optics is specialized in laser beam and terahertz source measurement and analysis. With an outstanding 50-year track record of innovation, developing and providing state-of the-art technologies to the laser market, Gentec-EO has become The Expert of the laser beam measurement field.

For all sorts of laser applications from the factory to the hospital, laboratory and research center, Gentec-EO offers the broadest range of off-the-shelf and custom solutions, and stands ready to serve you now and in the future.

More from this author